We

have our own

facilities at McGill University, which include nonstandard experimental

setup for unique experiments at small length scales and

in-situ

(we image the material at high and low magnifications in

real time as the material is deformed or fractured).

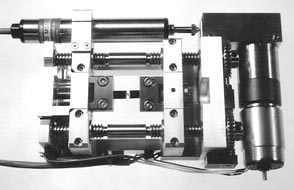

Miniature Loading Stage

| We use this small

mechanical loading stage for a wide variety of tests, from cyclic

loading on small mice bones to fracture tests on seashells. The stage

is small enough to fit under our optical microscope or our scanning

probe microscope. This allows for in-situ testing, where we can image

the material as it is deformed. The stage is controlled with a

computer-controlled (with feedback on force or displacement) which

enables a wide variety of testing programs. We use this machine with

different types fixtures, some custom made. These include tensile, 3

and 4 point bending, compression, indentation. Our load cells include

100 lbs, 25 lbs,5 lbs and 20 grams |

|

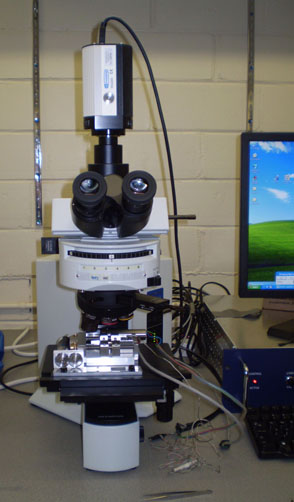

Olympus upright optical

microscope

We use this microscope for a variety of purposes, mostly microstructure

characterization for which we have differential interference contrast

and white light / fluorescence capabilities and a high resolution CCD

camera. Our mechanical loading stage also fits on the microscope stage

so we can image samples as they are deformed. An important implication

is that we can use the images to measure strain with a great accuracy,

using digital image correlation.

|

|

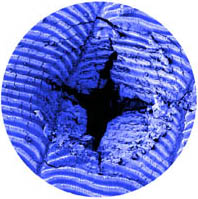

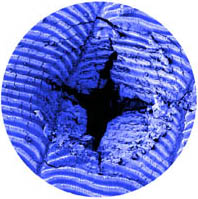

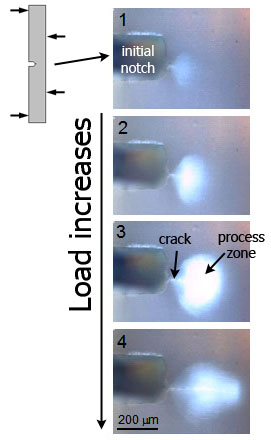

Example of in-situ

imaging of a propagating crack in nacre from a seashell

|

Veeco Nanoman Scanning Probe Microscope (SPM)

The

scanning

probe microscope is an extremely versatile piece of equipment used for

imaging surfaces with nanometers resolution but also to actually

interrogate surface mechanically (elasticity, strength, friction...) ,

or even pull on single molecules (force spectroscopy). An interesting

setup is to fit the mechanical stage underneath the microscope in order

to monitor how the microstructure of materials evolves when mechanical

stresses are applied. This setup allows great image resolution on

sample in wet conditions, making it perfect for in-situ mechanical

tests on hydrated biological materials.

Intermediate load

mechanical testing

platform (in construction)

Large

specimens and

structures are tested on a traditional universal tensile machine, while

on the other end the mechanics of single molecules can be interrogated

using an atomic force microscope (AFM). Between these two extremes

there is a wide gap in terms of force and imaging resolution, which we

are filling with new :intermediate" experimental setup.

We also use the

following equipements

and facilities:

*

Nanoindenter (Hysitron Triboscope) used to "poke" materials at depth of

micrometers down to a few nanometers

* Universal tensile machine (UTM) used

to test large

samples or structures

* Precision diamond saw used to carve

millimeter

size samples for mechanical testing

* Polishing facilities to prepare

surfaces for

imaging

* Electron Microscopes at the

FEMR

* Micro Computer Tomography at

the

Bone

center

* Chemical Facilities in the Otto Mass

building

* Microfabrication at the

McGill

Nanotools microfab (MNM)